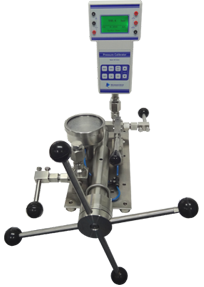

We at GSR Laboratory uses data acquisition unit with standard temperature, humidity sensors calibrated and certified by Accredited Laboratories to perform the mapping services. To maintain the quality control and safety of the product, seasonal mapping of temperature and humidity distribution of manufacturing, packing, storage facilities are performed.

A complete Temperature, Humidity Mapping solution

Placement of sensors is based on the protocol, guidelines and our standards. We install sensors on customer requirement. The selection sensors depend on the application and purpose of the mapping services. The conditions of mapping include with load, without load, open door, closed door, presence of man power. Based on the climatic conditions sensors will be placed as per the customer needs. The sensors are selected and placed on different locations are connected to the data acquisition unit. The data acquisition unit scans each channels, stores the readings or data. The start, close and restart time are programmed according to the requirements of the customer. Stored readings or data are uploaded to a computer for further analysis. The readings or data are generated in Excel and Graphical forms. The readings and data will give the complete status of temperature, humidity distribution. The certificate incorporating all the above results will give customer a very clear picture on the distribution of temperature, humidity. If any of the results do not comply with the requirements of the mapping, customer will decide incorporation of changes in their systems. The analysis of the temperature, humidity distribution through validation or mapping will help customer to ensure that the products are manufactured, processed, packed and stored in good condition.